Polymer Memory

Imagine a time when your mobile will be your virtual assistant and will need far more than the 8k and 16k memory that it has today, or a world where laptops require gigabytes of memory because of the impact of convergence on the very nature of computing. How much space would your laptop need to carry all that memory capacity? Not much, if Intel's project with Thin Film Electronics ASA (TFE) of Sweden works according to plan. TFE's idea is to use polymer memory modules rather than silicon-based memory modules, and what's more it's going to use architecture that is quite different from silicon-based modules.

While microchip makers continue to wring more and more from silicon, the most dramatic improvements in the electronics industry could come from an entirely different material plastic. Labs around the world are working on integrated circuits, displays for handheld devices and even solar cells that rely on electrically conducting polymers—not silicon—for cheap and flexible electronic components. Now two of the world’s leading chip makers are racing to develop new stock for this plastic microelectronic arsenal: polymer memory. Advanced Micro Devices of Sunnyvale, CA, is working with Coatue, a startup in Woburn, MA, to develop chips that store data in polymers rather than silicon. The technology, according to Coatue CEO Andrew Perlman, could lead to a cheaper and denser alternative to flash memory chips—the type of memory used in digital cameras and MP3 players. Meanwhile, Intel is collaborating with Thin Film Technologies in Linkping, Sweden, on a similar high capacity polymer memory.

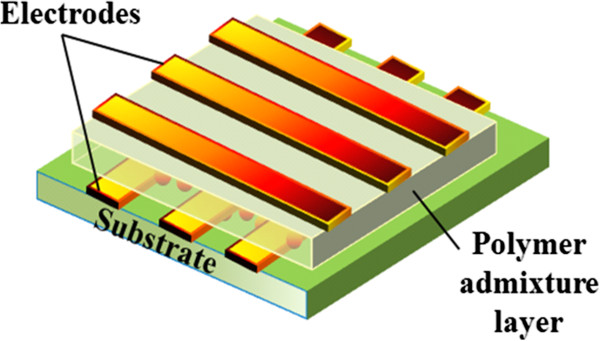

Polymer-based memory modules, as against silicon-based ones, promise to revolutionize the storage space and memory capabilities of chips. Coatue’s polymer memory cells are about one-quarter the size of conventional silicon cells. And unlike silicon devices, the polymer cells can be stacked that architecture could translate into memory chips with several times the storage capacity of flash memory. By 2004, Coatue hopes to have memory chips on the market that can store 32 gigabits, outperforming flash memory, which should hold about two gigabits by then, to produce a three- dimensional structure.

The fundamental idea of all these technologies is the bistable nature possible for of the selected material which is due to their difference in behavior of internal dipoles when electric field is applied. And they retain those states until an electric field of opposite nature is applied. FeRAM works on the basis of the bistable nature of the centre atom of selected crystalline material. A voltage is applied upon the crystal which in turn polarizes the internal dipoles up or down. I.e. actually the difference between these states is the difference in conductivity. Non –Linear FeRAM read capacitor,

i.e., the crystal unit placed in between two electrodes will remain in the direction polarized(state) by the applied electric field until another field capable of polarizing the crystal’s central atom to another state is applied.

polymer-memory-8917-JmWxMrb.pptx (607 KB)

polymer-memory-8917-1l0Qyh5.docx (266 KB)